Mục lục

Toggle1. Introduction to robotic systems in manufacturing

What are robotic systems?

Robotic systems in manufacturing refer to automated machines designed to perform repetitive, high-precision, and labor-intensive tasks. These systems play a crucial role in Industry 4.0 transformation, helping businesses optimize production, improve efficiency, and enhance product quality. Robotics in manufacturing is no longer a luxury but a necessity for companies aiming to stay competitive in an increasingly automated industrial landscape.

Why are manufacturers investing in robotics?

The adoption of robotic automation solutions is growing rapidly due to its significant advantages:

- Increased Productivity & Precision – Robots can operate 24/7 with minimal downtime, ensuring consistent production output.

- Reduced Human Labor Costs & Workplace Injuries – By automating hazardous tasks, businesses can minimize risks and reduce dependence on manual labor.

- Improved Consistency & Operational Efficiency – AI-driven robotic systems deliver precise, repeatable results, reducing errors and material waste.

As industries shift towards smart manufacturing, integrating robotic systems is becoming a key strategy to drive efficiency and maintain a competitive edge.

2. Key Applications of Robotic Systems in Manufacturing

2.1 Assembly Line Automation

Automating assembly lines with industrial robotics significantly enhances production speed and precision. High-speed robotic arms assemble electronic devices, automotive components, and consumer goods with unmatched accuracy. Additionally, collaborative robots (Cobots) are increasingly used in modern factories, working alongside human operators to improve efficiency and safety.

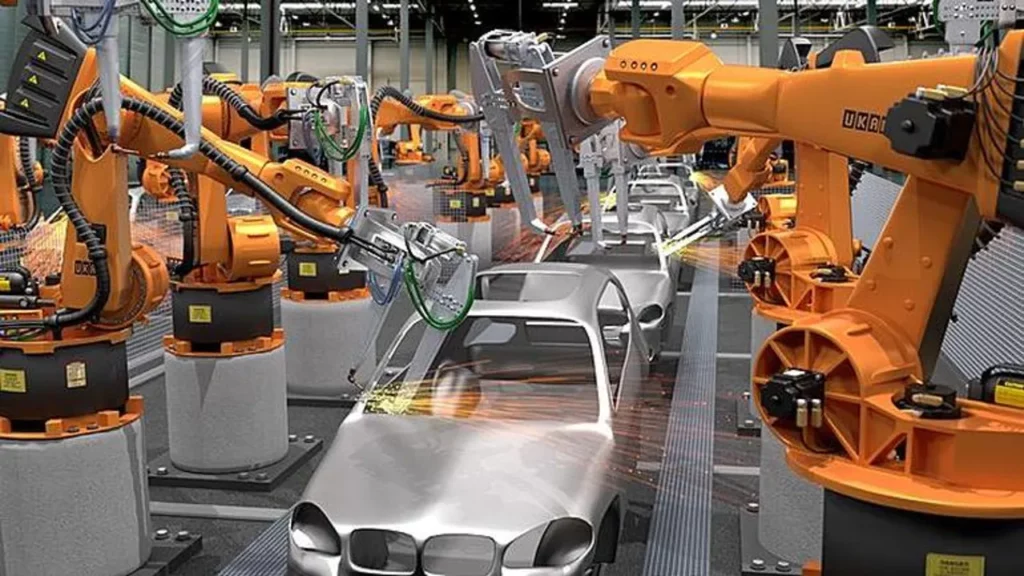

2.2 Robotic Welding & Cutting

AI-driven robotic welding systems ensure high-precision and consistent weld quality, reducing defects in industries like automotive, aerospace, and heavy machinery. Meanwhile, laser and plasma cutting robots are widely used for metal fabrication, offering greater accuracy, speed, and reduced material waste compared to traditional methods.

2.3 Material Handling & Logistics Automation

Advanced material handling robotics streamline warehouse operations, improving inventory management and logistics. Key technologies include:

- Automated Guided Vehicles (AGVs) – Transport materials efficiently within factories.

- AI-powered robotic arms – Optimize sorting, palletizing, and order fulfillment, reducing bottlenecks in supply chains.

2.4 Quality Inspection & AI-Powered Defect Detection

Machine vision technology is transforming quality control in manufacturing. AI-enhanced robotic systems analyze products in real time, detecting defects faster and more accurately than human inspectors. Additionally, predictive maintenance powered by AI helps companies monitor equipment health, reducing downtime and maintenance costs.

3. Advantages of robotic systems integration in manufacturing

The integration of robotic systems in manufacturing brings numerous advantages, significantly enhancing productivity, cost efficiency, workplace safety, and scalability. As businesses strive to improve operational efficiency and product quality, robotics has become a key enabler of smart manufacturing and Industry 4.0.

Higher Productivity & Output Quality

One of the biggest advantages of robotic automation is its ability to maintain continuous production 24/7 without the need for breaks, shift changes, or rest periods. Unlike human workers, robots can operate with unwavering precision and consistency, ensuring steady production output at all times. This continuous operation significantly increases manufacturing throughput and shortens lead times.

Moreover, robotic systems reduce human error, leading to greater product uniformity and fewer defects. Advanced robotic automation, equipped with AI-powered quality control, can detect and correct issues in real-time, minimizing the need for rework and waste. This results in higher product quality, improved customer satisfaction, and a more reliable supply chain.

Cost Efficiency & Reduced Waste

By optimizing resource utilization, robotic systems help manufacturers lower production costs over time. Robots can maximize material efficiency, reduce errors, and streamline production workflows, leading to lower operational expenses.

Additionally, robotic automation minimizes material waste by ensuring precise and controlled manufacturing processes. Whether in cutting, welding, assembly, or packaging, robots can execute tasks with extreme accuracy, reducing scrap rates and optimizing the use of raw materials. This not only improves overall profitability but also supports sustainable manufacturing initiatives by reducing environmental impact.

Workplace Safety & Risk Reduction

Manufacturing environments often involve hazardous conditions, such as high temperatures, heavy machinery, toxic chemicals, and repetitive motions that can cause workplace injuries. By integrating robotic systems, companies can reduce worker exposure to dangerous environments, enhancing overall workplace safety.

Instead of assigning human workers to physically demanding, repetitive, or high-risk tasks, manufacturers can deploy robots to handle these operations. This allows employees to focus on higher-value, strategic tasks such as system monitoring, programming, and process optimization, leading to a more skilled and engaged workforce.

Scalability & Flexibility

One of the most significant advantages of robotic automation solutions is their ability to scale with business growth. Customizable robotic solutions can be tailored to various industries, enabling manufacturers to seamlessly expand production lines as demand increases.

Furthermore, robots can be easily reprogrammed and reconfigured to accommodate new product designs, evolving production requirements, and changing industry trends. Unlike traditional machinery, which may require extensive modifications for new applications, robotic systems offer greater flexibility, allowing manufacturers to adapt quickly to market demands and maintain a competitive edge.

4. Challenges in robotic systems implementation & solutions

High initial investment → Scalable adoption models: Many businesses hesitate due to high upfront costs. However, robot leasing options and modular automation provide cost-effective adoption strategies.

Technical integration complexity → Custom software solutions: Integrating robotics with existing manufacturing processes can be challenging. Custom AI-driven software ensures smooth compatibility with production systems.

Workforce training & adaptation → Upskilling programs: The shift towards robotic automation requires operator training and upskilling initiatives to ensure seamless human-machine collaboration.

5. Industries benefiting from robotic integration

Automotive Manufacturing: Precision welding, assembly automation, and quality inspection enhance vehicle production efficiency.

Logistics & Warehousing: Smart AGVs, robotic sorting systems, and automated picking solutions optimize supply chain management.

Electronics & Semiconductor Industry: AI-enhanced robotic micro-assembly and defect inspection improve electronic device manufacturing.

Metal Fabrication & Heavy Machinery: High-precision robotic cutting, milling, and welding systems enhance production capabilities in metalworking industries.

6. The future of robotics in smart manufacturing

The next evolution of robotic systems will be driven by artificial intelligence, IoT connectivity, and sustainability.

- AI & Machine Learning in Robotics: AI-powered self-learning robots will continuously optimize workflows, making real-time adjustments based on production demands.

- 5G & IoT-Connected Robotics: Faster data exchange enables seamless robotic communication, improving efficiency in smart factories.

- Sustainable robotics: Energy-efficient robotic systems will help manufacturers reduce carbon footprints, aligning with global sustainability goals.

As robotic automation solutions become more sophisticated, manufacturers embracing smart robotics will gain a competitive edge in efficiency, productivity, and cost reduction.

Conclusion

Robotic systems integration is revolutionizing modern manufacturing, offering unmatched efficiency, precision, and scalability. Companies investing in AI-driven robotics and smart automation will be well-positioned for the future of Industry 4.0.