Mục lục

ToggleThe industrial landscape is undergoing a seismic shift as automation and robotics redefine how factories operate, compete, and scale in the digital age. While many manufacturers still rely on labor intensive processes vulnerable to errors and inefficiencies, the rise of intelligent automation offers a transformative path forward. In this exclusive article by FBC, we explore how automation and robotics are not just enhancing productivity but reshaping the very foundation of industrial strategy empowering manufacturers to respond faster, work smarter, and build future-ready operations.

What are automation and robotics?

Understanding the fundamental concepts, capabilities, and relationships between automation and robotics technologies provides the foundation for strategic decision-making and successful implementation in manufacturing environments.

Industrial automation uses control systems like PLCs, SCADA, and DCS to manage manufacturing processes with minimal human input, improving consistency, efficiency, and data-driven optimization. Applications include process control, quality inspection, material handling, and production planning. Platforms like Schneider Electric’s EcoStruxure showcase the impact, with up to 25% efficiency gains across global operations.

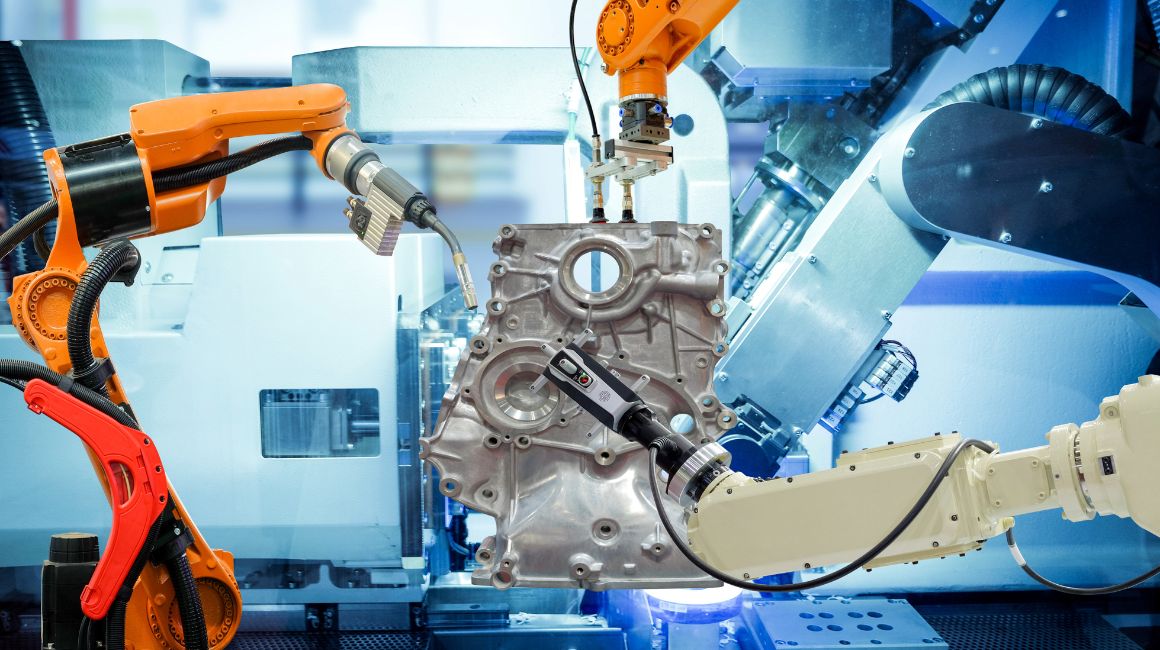

Industrial robotics focuses on precise, repetitive physical tasks such as assembly, welding, and packaging, using intelligent machines like articulated and collaborative robots. While automation manages systems and processes, robotics handles motion and manipulation. When combined, as seen at Tesla’s Gigafactory, they create intelligent, high-performance environments with 99.9% quality and 40% efficiency improvements.

Evolution of the robotics and automation industry

The robotics and automation industry has experienced remarkable transformation from simple mechanization to sophisticated, AI enhanced systems that represent the cutting edge of manufacturing technology.

Automation and robotics have evolved from basic mechanization to AI powered systems that enable autonomous decision-making and real-time optimization. Modern solutions integrate machine learning, computer vision, and adaptive controls, significantly boosting performance and reducing programming and maintenance needs as seen with Fanuc’s AI robots improving efficiency by 30% and cutting programming time by 50%.

The global automation market reached $89B in 2024, led by Asia-Pacific with 58% of installations. Automotive and electronics dominate adoption, while ASEAN nations like Vietnam and Thailand show rapid growth. CNC machines, when integrated with robotics as in DMG Mori’s CELOS systems enable highly efficient, unmanned operations with 30% faster cycles and 45% better quality consistency.

Benefits of industrial automation and robotics

The strategic advantages of automation and robotics implementation extend across all aspects of manufacturing operations, delivering measurable improvements that directly impact competitiveness and profitability.

Reduced operational costs

Automation and robotics significantly reduce operational costs through labor savings, material waste reduction, and energy efficiency. Automated systems eliminate overtime, reduce staff needs, and minimize training and turnover costs. They also improve material utilization by 15–25% and cut energy expenses by 12–20%. Foxconn’s global automation initiative cut costs by 23% and boosted capacity by 35%, enhancing profitability and competitiveness.

Higher production speed and scalability

Production speed improvements result from automated systems that operate at optimal speeds without fatigue or performance degradation. Robotic systems can perform operations 2-5 times faster than human workers while maintaining precision and consistency throughout extended production runs.

Scalability advantages enable manufacturers to increase production capacity rapidly without proportional increases in workforce or facility requirements. Automated systems can operate additional shifts, extend operating hours, and increase throughput through optimization without significant infrastructure investments.

Enhanced precision and quality control

Precision improvements result from servo-controlled motors, advanced sensors, and feedback systems that achieve positioning accuracy of ±0.01mm and repeatability levels of ±0.005mm in standard applications. These precision capabilities enable manufacturing of complex components that meet stringent tolerance requirements impossible to achieve through manual operations.

Quality consistency eliminates human variability factors that contribute to defect rates and quality inconsistencies. Automated systems perform operations identically every time while continuously monitoring quality parameters and adjusting processes automatically to maintain optimal performance.

Real-time data collection and analytics

Sensor networks integrated throughout automated systems collect detailed operational data including equipment performance, environmental conditions, quality parameters, and production metrics. This data provides unprecedented visibility into manufacturing operations while enabling predictive analytics and optimization opportunities.

Real-time analytics enable immediate response to operational issues, quality deviations, and efficiency opportunities while providing management dashboards that support strategic decision-making. These capabilities enable manufacturers to optimize operations continuously while identifying improvement opportunities and potential problems before they impact performance.

Safer work environments for operators

Hazard elimination results from automated systems that perform dangerous operations including heavy lifting, exposure to chemicals, high-temperature processes, and repetitive motions that cause ergonomic injuries. These systems operate in environments that would be unsafe for human workers while maintaining consistent performance and safety standards.

Accident reduction through automation typically achieves 40-60% decreases in workplace injuries while eliminating fatalities associated with equipment operation and hazardous processes. Automated safety systems monitor conditions continuously and implement protective measures automatically when unsafe conditions are detected.

Greater flexibility in multi-product manufacturing

Modern automation and robotics systems provide manufacturing flexibility that enables rapid changeovers between products while maintaining efficiency and quality standards across diverse product lines.

Programmable flexibility enables automated systems to produce different products through software changes rather than hardware modifications. These systems can switch between product variants quickly while maintaining optimal performance and quality standards throughout production runs.

Common use cases of automation and robotics systems

Manufacturing organizations implement automation and robotics across diverse applications that address specific operational challenges while delivering measurable improvements in efficiency, quality, and cost management.

Automation of repetitive assembly line tasks

Repetitive assembly operations represent ideal applications for automation and robotics implementation, delivering consistent quality while eliminating human fatigue and variability that impact production efficiency and product quality.

Automated assembly systems integrate vision guidance, force feedback, and precision positioning to perform complex assembly operations with accuracy and speed that exceeds human capabilities. These systems can handle delicate components, apply precise forces, and verify assembly quality while operating continuously without performance degradation.

Robotics in packaging, sorting, and inspection

Packaging, sorting, and inspection operations leverage robotics capabilities for speed, precision, and consistency that significantly exceed human performance while operating in challenging environments and handling diverse product types.

Robotic packaging systems integrate vision guidance, end-effector customization, and adaptive control to handle products of varying sizes, shapes, and materials while maintaining gentle handling that prevents damage. These systems achieve packaging speeds 3-5 times faster than manual operations while ensuring consistent presentation and protection.

Automated CNC machining and smart manufacturing

CNC machining automation represents sophisticated manufacturing technology that combines precision machining with intelligent control systems to produce complex components with micron-level accuracy while optimizing productivity and quality.

Smart CNC systems integrate adaptive control algorithms, real-time monitoring, and predictive analytics to optimize cutting parameters automatically based on material properties, tool condition, and quality requirements. These systems maintain optimal performance while extending tool life and preventing quality issues.

Logistics and warehouse robotics systems

Warehouse and logistics automation utilizes mobile robotics, automated storage and retrieval systems, and intelligent control software to optimize material handling while reducing costs and improving accuracy in complex distribution operations.

Automated guided vehicles (AGVs) and autonomous mobile robots (AMRs) transport materials throughout facilities while optimizing routes, avoiding obstacles, and coordinating with other systems. These systems eliminate manual material handling while improving efficiency and reducing workplace injuries.

Predictive maintenance and remote diagnostics

Predictive maintenance automation combines sensor networks, data analytics, and machine learning to optimize equipment maintenance while preventing failures and reducing maintenance costs through intelligent scheduling and condition-based maintenance strategies.

Condition monitoring systems continuously analyze equipment performance through vibration sensors, thermal imaging, oil analysis, and acoustic monitoring to identify developing problems before they cause failures. These systems provide advance warning of maintenance needs while optimizing maintenance scheduling.

Leading robotics and automation companies and solutions

Global automation leaders like Siemens, ABB, Rockwell Automation, and Schneider Electric offer end-to-end solutions that combine control systems, robotics, software, and analytics to optimize manufacturing performance. Their platforms such as Siemens’ Digital Enterprise, ABB’s Ability, Rockwell’s FactoryTalk, and Schneider’s EcoStruxure drive digital transformation and operational efficiency across industries.

In robotics, companies like Fanuc, KUKA, Universal Robots, and Yaskawa lead CNC integration and collaborative automation. Meanwhile, startups like Bright Machines, Path Robotics, Kindred AI, and Symbotic are disrupting traditional models with AI driven, flexible automation systems tailored for rapid reconfiguration, autonomous welding, complex manipulation, and warehouse optimization.

Challenges and limitations of automation technologies

Automation technologies offer significant benefits but come with key challenges. High upfront costs ranging from $500,000 to $5 million along with installation, integration, and training expenses, require long-term financial planning. Implementation can take 6–18 months and demands careful project management to avoid production disruptions. Workforce impact is another concern, with job displacement in routine roles requiring reskilling, change management, and new training programs to support emerging technical positions.

Technical barriers also pose risks. Integrating modern automation with legacy systems can be complex and costly, while increased connectivity introduces cybersecurity vulnerabilities that require strong protection measures. Automation failures may cause system-wide disruptions, highlighting the need for redundancy planning. Additionally, managing the vast data generated by automated systems necessitates advanced IT infrastructure and robust data governance strategies.

Future trends in robotics and automation systems

The evolution of automation and robotics continues accelerating through integration with emerging technologies that promise to further transform manufacturing capabilities and competitive dynamics.

AI and machine learning-enhanced robotics

The evolution of automation and robotics continues accelerating through integration with emerging technologies that promise to further transform manufacturing capabilities and competitive dynamics.

- AI and machine learning integration allows robots to learn, self-optimize, and adapt without manual programming.

- Adaptive learning helps robots improve performance by adjusting to changing materials, environments, and requirements.

- Computer vision + ML enables real-time object recognition, quality assessment, and flexible handling of diverse tasks.

- Predictive analytics allows robots to forecast maintenance needs and avoid failures, extending lifespan and reliability.

- Boston Dynamics’ Atlas robot showcases future potential with dynamic movement, balance, and environmental adaptability in complex manufacturing.

Collaborative robots (Cobots) in SMEs

Collaborative robotics represents democratization of automation technology through systems designed for safe human-robot interaction, ease of deployment, and affordability that makes automation accessible to small and medium enterprises.

- Collaborative robots (cobots) make automation accessible for SMEs with safe, affordable, and easy-to-deploy systems.

- Built-in safety features like force limiting and collision detection allow cobots to work alongside humans without cages or barriers.

- User-friendly programming enables quick setup and reconfiguration by in-house staff, reducing reliance on robotics specialists.

- Lower costs and minimal infrastructure needs make cobots ideal for small-scale or specialized production tasks.

- Universal Robots has deployed 50,000+ cobots globally, helping SMEs boost productivity by 15–25% in applications like packaging, machine tending, and inspection.

Sustainable automation for green manufacturing

Environmental sustainability considerations drive automation development toward energy-efficient systems, waste reduction capabilities, and circular economy support that align manufacturing operations with corporate sustainability objectives.

- Sustainable automation focuses on energy efficiency, waste reduction, and support for circular economy initiatives.

- Energy savings of 15–25% are achieved through smart controls and optimized operations, lowering both emissions and costs.

- Waste reduction is enabled by precise control and quality optimization, with some systems reaching near-zero waste levels.

- Eco-friendly materials and processes (e.g., recyclable parts, biodegradable lubricants) reduce lifecycle environmental impact.

- Interface Inc.’s Mission Zero proves automation can achieve carbon neutrality without sacrificing productivity or quality.

The future of manufacturing belongs to those who can adapt and automation and robotics are at the core of that transformation. These technologies are no longer emerging trends, but proven solutions driving operational excellence, resilience, and innovation across industries. Businesses that invest today will be the leaders of tomorrow. To stay ahead of the curve, explore more insights, tools, and solutions at FBC, your trusted partner in industrial advancement. Follow our website for the latest updates and discover how automation and robotics can future-proof your production strategy.