Mục lục

ToggleIn today’s fiercely competitive markets, speed is everything and rapid prototyping has become the go‑to strategy for reducing product development cycles. Traditional design‑to‑production timelines often stretch for months, but industries can no longer afford such delays. In this article, FBC examines how businesses across manufacturing, electronics, and consumer goods are leveraging cutting‑edge tools and techniques to accelerate innovation without sacrificing quality.

What is rapid prototyping?

Rapid prototyping encompasses advanced manufacturing technologies and methodologies that enable creation of physical prototypes directly from digital designs within hours or days, fundamentally transforming traditional product development approaches through speed, flexibility, and iterative capability.

Definition and purpose in product development

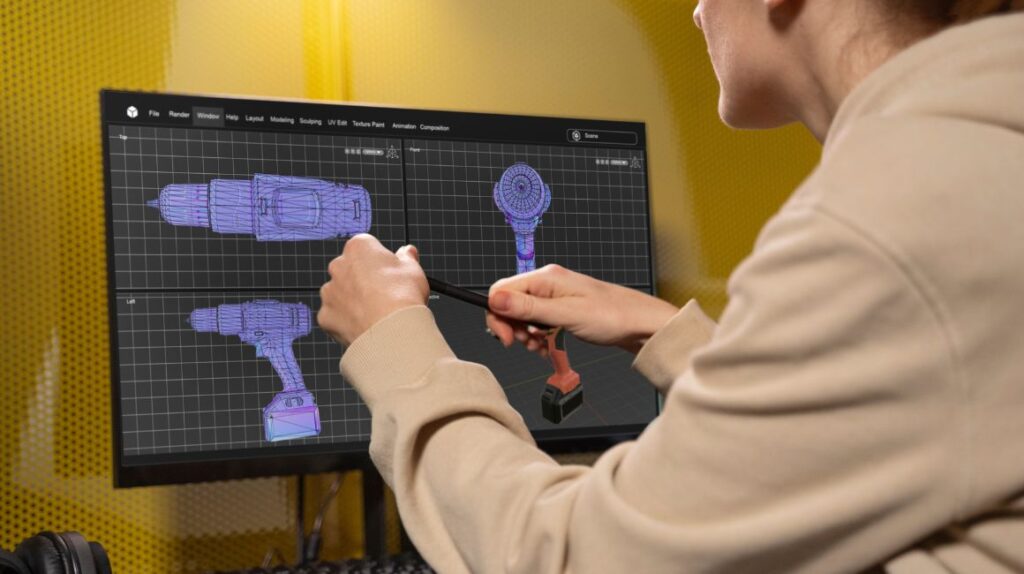

Rapid prototyping marks a major shift from traditional prototype development by transforming CAD designs directly into physical models through additive, subtractive, or hybrid manufacturing delivering functional parts in days instead of weeks or months. Its purpose goes beyond visualization, supporting functional testing, design validation, and iterative refinement to catch and fix issues early, reducing costs and delays.

Applications include concept validation, form‑fit‑function testing, user interface evaluation, and market trials for customer feedback before full‑scale production. The technology also enables parallel development, allowing multiple design variations to be produced and compared physically for faster, more informed decision‑making.

Key differences between traditional prototyping and rapid prototyping

Traditional prototyping relied on handcrafting, basic machining, and costly tooling, making iterations slow, expensive, and limited in functionality. It often took 4–12 weeks to produce a prototype, compared to hours or days with rapid prototyping, which removes tooling needs and lowers labor costs. Rapid prototyping also supports far greater design complexity, enabling intricate geometries and assemblies that traditional methods couldn’t achieve. Its precision and repeatability—often within ±0.1 mm—allow functional testing with accurate, consistent results, while easily incorporating multiple materials or properties in a single build.

How the rapid prototyping process works

The rapid prototyping workflow integrates digital design tools with advanced manufacturing technologies to create seamless transitions from concept to physical prototype while enabling iterative improvements throughout development cycles.

From 3D model to physical prototype

Rapid prototyping begins with a detailed 3D CAD model optimized for the chosen process, then converted into formats like STL or G‑code with supports and toolpaths planned for efficiency. Materials and parameters are selected for the intended tests, often with automated optimization. Sensors monitor production in real time to ensure quality, and post‑processing such as support removal and finishing completes the functional prototype for evaluation.

Iterative design and testing approach

Rapid prototyping supports iterative design by enabling fast feedback cycles, with prototypes produced in 24–48 hours for testing and comparison. Functional testing reveals real‑world performance, material behavior, and user feedback beyond what simulations can provide. Results are quickly integrated into design modifications, creating continuous improvement and reducing risks through early issue detection. Documentation and version control often managed via PLM systems track design evolution and ensure regulatory compliance.

Rapid integration with CAD and simulation tools

Modern rapid prototyping systems integrate directly with CAD and simulation tools, enabling seamless data transfer, design rule checks, and manufacturability analysis to prevent production issues. Simulation methods like FEA, CFD, and thermal modeling predict performance, reducing the number of prototype iterations needed. Optimization tools use these results to suggest or auto‑generate improved designs suited for rapid prototyping. Automated workflows connect CAD, simulation, and production, minimizing manual work, ensuring consistent quality, and shortening development cycles.

Types of rapid prototyping techniques

Rapid prototyping encompasses diverse manufacturing technologies, each optimized for specific materials, geometries, and functional requirements that determine their suitability for particular applications and development objectives.

Additive manufacturing (3D Printing)

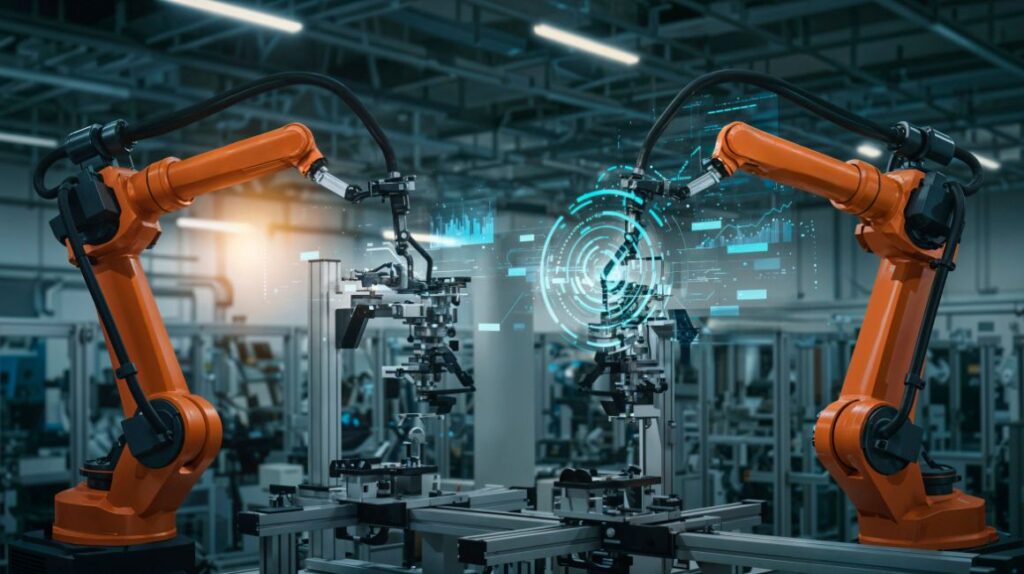

Additive manufacturing technologies build prototypes layer by layer from digital models, enabling complex geometries and internal features impossible to produce through traditional manufacturing methods while providing design freedom that optimizes prototype functionality.

- Stereolithography (SLA): Stereolithography (SLA) uses UV lasers to cure liquid resin layer by layer, producing high‑resolution prototypes with ±0.1 mm accuracy, fine details, and smooth surfaces ideal for form‑fit‑function testing. It supports diverse resins, completes parts in 4–8 hours, and often requires minimal post‑processing.

- Selective Laser Sintering (SLS): Selective Laser Sintering (SLS) fuses powdered materials with lasers to produce strong, functional prototypes without support structures, enabling complex geometries and moving assemblies. It works with materials like nylon, glass‑ or aluminum‑filled nylon, and metals, delivering injection‑mold‑like strength for realistic functional testing while reducing post‑processing and material waste.

- Fused Deposition Modeling (FDM): Fused Deposition Modeling (FDM) extrudes heated thermoplastic filaments layer by layer, offering a cost‑effective way to create durable prototypes for functional testing. It supports materials like ABS, PLA, PETG, nylon, and carbon‑fiber composites, accommodates large build volumes, and delivers mechanical properties suitable for realistic validation across diverse industrial applications.

- Digital Light Processing (DLP): Digital Light Processing (DLP) cures entire resin layers at once using digital projectors, delivering faster builds than laser‑based systems while maintaining fine resolution down to 0.035 mm. It supports a range of resins, produces smooth, detailed parts for aesthetic and functional testing, and enables efficient batch production for iterative development.

Subtractive manufacturing (Rapid Prototyping CNC)

CNC rapid prototyping uses subtractive manufacturing to machine prototypes from production materials such as metals, engineering plastics, and composites, delivering realistic mechanical properties for functional testing. Multi‑axis machining achieves complex geometries, tight tolerances down to ±0.025 mm, and surface finishes approaching Ra 0.1 µm. It supports heat treatment and finishing for production‑quality performance, while hybrid workflows combine additive for complex features with CNC for precision surfaces, optimizing cost, quality, and testing capability.

Advantages of using rapid prototyping

Rapid prototyping transforms product development by compressing cycles from months to days, enabling faster launches, multiple parallel design iterations, and agile responses to feedback. Prototypes can be produced within 24–72 hours, supporting early flaw detection and cost savings by identifying issues before costly tooling or production phases.

Iterative testing improves performance, reduces risks, and ensures quality meets or exceeds requirements, while enhancing collaboration through tangible models that align teams, engage stakeholders, and validate customer needs. It also enables in‑depth usability, form‑fit‑function, and assembly testing, providing real‑world insights that simulations alone cannot match.

Industrial applications of rapid prototyping

Rapid prototyping supports a wide range of industries by enabling fast, flexible, and functional product development. In automotive and aerospace, it accelerates component validation, assembly fit checks, aerodynamic testing, and crash safety optimization under real‑world conditions. Consumer electronics manufacturers use it for rapid housing design, user interface refinement, thermal management validation, and EMI compliance testing.

In medical devices, it enables patient‑specific solutions, biocompatibility testing, regulatory validation, and surgical planning with anatomical models. It also supports low‑volume manufacturing, producing functional parts, bridge production runs, spare parts, custom components, and tooling or fixtures quickly and cost‑effectively.

Future trends in rapid prototyping

The evolution of rapid prototyping continues accelerating through integration with artificial intelligence, advanced materials, and sustainable technologies that promise to further transform product development capabilities and competitive dynamics.

Integration with AI-driven generative design

AI‑driven generative design integrates with rapid prototyping to automatically create and optimize designs that push beyond traditional constraints. Generative algorithms balance performance needs with manufacturing limits, producing lightweight, cost‑efficient prototypes. Machine learning refines these designs using real‑world testing data, while automated iteration closes the loop between design and fabrication for continuous improvement. Intelligent parameter optimization further enhances quality and reduces production time by adjusting process settings automatically.

Faster printing and machining technologies

Next‑generation manufacturing technologies are greatly increasing rapid prototyping speed without sacrificing quality. High‑speed 3D printing methods like CLIP and multi‑laser systems can produce parts 10–100× faster while preserving accuracy, and multi‑material printing creates functional assemblies with varied properties in one build. Ultra‑fast CNC machining now rivals additive manufacturing cycle times while delivering production‑grade materials and finishes. Automated post‑processing further cuts labor and ensures consistent quality through robotic finishing and assembly.

Prototyping with sustainable and composite materials

Sustainable rapid prototyping leverages eco‑friendly and composite materials to reduce environmental impact while delivering high performance. Bio‑based and recycled materials support circular economy goals, offering functional properties for testing with a smaller carbon footprint. Composite prototyping combines advanced fibers with 3D printing to achieve near‑production strength for validation, while biodegradable materials provide short‑term solutions for design testing without disposal concerns.

Rapid prototyping is more than just a technical process it’s a strategic advantage that can determine who leads and who lags in today’s fast‑moving industries. By adopting agile design workflows and embracing flexible manufacturing methods, companies can cut lead times, lower costs, and bring superior products to market ahead of competitors. The future belongs to innovators who can adapt and iterate quickly.

Follow FBC to stay up to date with the latest rapid prototyping technologies, success stories, and expert guidance—or to explore solutions tailored to your development challenges.