Mục lục

ToggleIn this era of digital transformation, machine learning in manufacturing is emerging as a game-changer, enabling predictive insights, intelligent automation, and real-time decision-making. This shift not only reduces downtime and operational waste but also drives product innovation and competitiveness. In this article by FBC, we explore how machine learning is revolutionizing the manufacturing industry, addressing long-standing inefficiencies and unlocking new opportunities for scalable, data-driven growth.

Machine learning adoption in the manufacturing industry

The widespread adoption of machine learning across manufacturing organizations reflects both technological maturation and compelling business imperatives that make implementation critical for survival in an increasingly competitive global marketplace.

Machine learning adoption in manufacturing is surging, with 84% of large firms and 67% of mid-size firms engaged. Global investment hit $12.4B in 2024, led by North America, Europe, and ASEAN. Automotive and electronics lead sector adoption, while ASEAN nations show the fastest growth. ROI is strong across use cases, with predictive maintenance yielding up to 280% returns.

Manufacturers are adopting machine learning to address global competition, labor shortages, rising regulatory demands, and the need for mass customization. ML enables real-time optimization of efficiency, quality, and costs. It supports flexible production, automates analytics and decision-making, and enhances workforce capabilities. Additionally, ML ensures supply chain resilience amid ongoing disruptions.

Core machine learning technologies used in manufacturing

Manufacturing applications leverage sophisticated machine learning technologies, each designed to address specific operational challenges and data characteristics inherent in production environments.

Predictive analytics for smarter decision-making

Predictive analytics empowers manufacturers to make proactive, data-driven decisions by forecasting future conditions. It improves planning, maintenance, quality, energy use, and supply chain resilience. Platforms like Schneider Electric’s EcoStruxure boost equipment effectiveness by up to 30%. Overall, predictive analytics enhances forecast accuracy, decision speed, and reduces costs significantly.

Intelligent process automation (IPA)

Intelligent Process Automation (IPA) enhances traditional automation by integrating machine learning for real-time, self-optimizing systems. It adjusts production, quality, maintenance, and energy use without human input. Platforms like ABB’s Ability demonstrate up to 18% productivity and 23% energy savings. IPA enables adaptive, efficient manufacturing through constant data-driven adjustments.

Computer vision for defect detection and visual inspection

Computer vision automates defect detection with greater speed, accuracy, and consistency than manual inspection. It identifies tiny flaws, learns from data, and adapts to new defect patterns. Systems like Cognex achieve 99.95% accuracy and cut inspection time by 85%. Overall, computer vision boosts detection by up to 60% and processing speed by up to 800%.

Neural networks and deep learning for optimization tasks

Neural networks and deep learning solve complex manufacturing optimization problems involving dynamic variables and constraints. They enhance process settings, quality predictions, supply chains, maintenance, and energy use. Platforms like Microsoft Azure IoT show 22% efficiency and 28% quality gains. Deep learning delivers continuous, intelligent optimization across operations.

Top 10 machine learning use cases in manufacturing

Machine learning applications in manufacturing deliver measurable improvements across all operational areas, transforming traditional approaches to production management, quality control, and business optimization.

Predictive maintenance to prevent equipment failure

Predictive maintenance represents the most successful and widely adopted machine learning application in manufacturing, transforming maintenance strategies from reactive and time-based approaches to intelligent, condition-based optimization that prevents failures while minimizing maintenance costs.

Implementation results demonstrate remarkable improvements across critical performance indicators. Unplanned downtime reductions of 40-55% are typical, with leading implementations achieving 75% reductions in unexpected equipment failures. Maintenance cost savings range from 25-35% through optimized scheduling, reduced emergency repairs, and improved parts inventory management.

Automated quality control systems

Machine learning-powered quality control systems revolutionize manufacturing quality assurance by providing continuous, high-precision inspection capabilities that identify defects and variations before they impact product quality, customer satisfaction, or regulatory compliance.

Quality control automation consistently delivers defect detection accuracy exceeding 99.7%, inspection speed increases of 400-600% compared to manual methods, and false positive reductions of 85% through intelligent pattern recognition. These improvements reduce waste, rework costs, and customer complaints while ensuring consistent product quality.

Audi’s quality control implementation showcases automated systems effectiveness in automotive manufacturing, where machine learning analysis of production data achieves 99.8% defect detection accuracy while reducing inspection time by 70%. This system processes over 2,000 vehicles daily while maintaining stringent quality standards across all production lines.

Demand forecasting for supply chain agility

Machine learning demand forecasting transforms supply chain management by providing accurate predictions of customer demand that enable optimized inventory management, production planning, supplier coordination, and resource allocation across complex manufacturing networks.

Advanced forecasting models analyze historical sales data, market trends, economic indicators, weather patterns, social media sentiment, promotional activities, and competitive actions to predict demand with accuracy levels exceeding 96% for established products and 88% for new product introductions.

Smart contract and document management

Machine learning applications in contract and document management automate routine administrative tasks while improving compliance monitoring, risk management, and operational efficiency across manufacturing organizations with complex supplier networks and regulatory requirements.

Document management automation delivers processing speed improvements of 600-900% compared to manual methods, accuracy improvements of 96% in data extraction tasks, compliance monitoring capabilities that identify 92% of potential issues before they impact operations, and cost reductions of 40-50% in administrative processing expenses.

Faster and more efficient product development cycles

Product development applications include design optimization where algorithms identify optimal component configurations, material selection where systems recommend materials based on performance and cost criteria, prototype optimization where systems predict performance outcomes, testing acceleration where systems identify critical test scenarios, and market analysis where systems predict customer acceptance and competitive positioning.

Development cycle improvements include design time reductions of 35-45%, prototype testing efficiency improvements of 55-70%, time-to-market acceleration of 30-40%, and development cost reductions of 20-30%. These improvements enhance competitive positioning while reducing innovation risks and resource requirements.

Production line optimization using real-time data

Real-time production optimization systems continuously analyze manufacturing data to adjust process parameters, coordinate production activities, balance workloads, and maximize overall equipment effectiveness while maintaining quality standards and meeting delivery commitments.

Production optimization results include throughput improvements of 18-28%, energy consumption reductions of 12-22%, overall equipment effectiveness improvements of 25-35%, and cycle time reductions of 15-25%. These improvements directly impact profitability through increased capacity, reduced operating costs, and improved resource utilization.

Enhanced cybersecurity through anomaly detection

Anomaly detection algorithms analyze network traffic patterns, user behavior, system performance metrics, access patterns, and communication protocols to identify potential security threats including malware infections, unauthorized access attempts, data exfiltration, and system compromises. These systems detect sophisticated attacks that traditional security methods might miss.

Cybersecurity improvements include threat detection speed improvements of 400-600%, false positive reductions of 78-88%, incident response time reductions of 65-75%, and security breach prevention rates of 94-97%. These improvements protect intellectual property, production systems, customer data, and business continuity from increasingly sophisticated cyber threats.

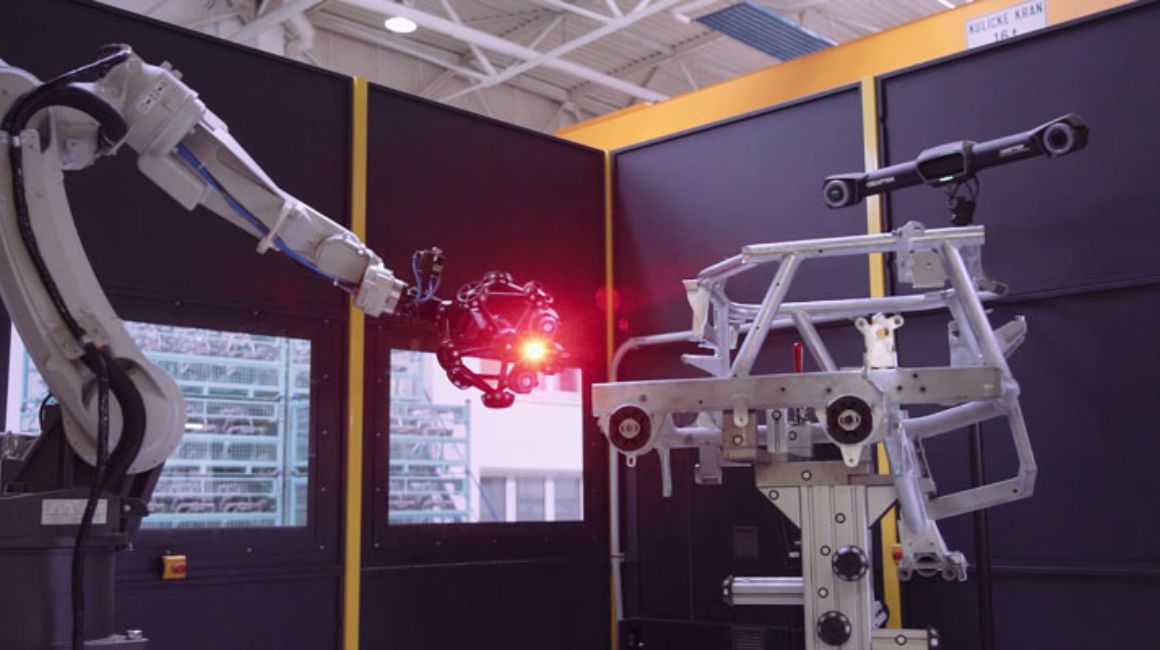

Robotics driven by machine learning algorithms

Intelligent robotics applications include adaptive grasping where robots adjust to varying object shapes and materials, precision assembly where robots compensate for part variations, collaborative robotics where robots work safely alongside humans, predictive maintenance where robots monitor their own condition, and autonomous navigation where robots optimize movement patterns.

Robotics improvements include precision improvements of 45-65%, programming time reductions of 55-75%, maintenance cost reductions of 35-45%, and productivity improvements of 25-35%. These enhancements expand robotics applications while reducing implementation and operating costs across diverse manufacturing environments.

Order and inventory management improvements

Inventory optimization systems analyze demand patterns, supplier performance, lead times, carrying costs, seasonality effects, and market conditions to determine optimal inventory levels for thousands of components simultaneously. These systems reduce inventory costs while improving service levels through intelligent optimization that balances multiple objectives.

Inventory management improvements include carrying cost reductions of 28-38%, stockout reductions of 45-55%, working capital optimization that frees 18-25% of inventory investment, and service level improvements that increase customer satisfaction by 15-20% through better product availability.

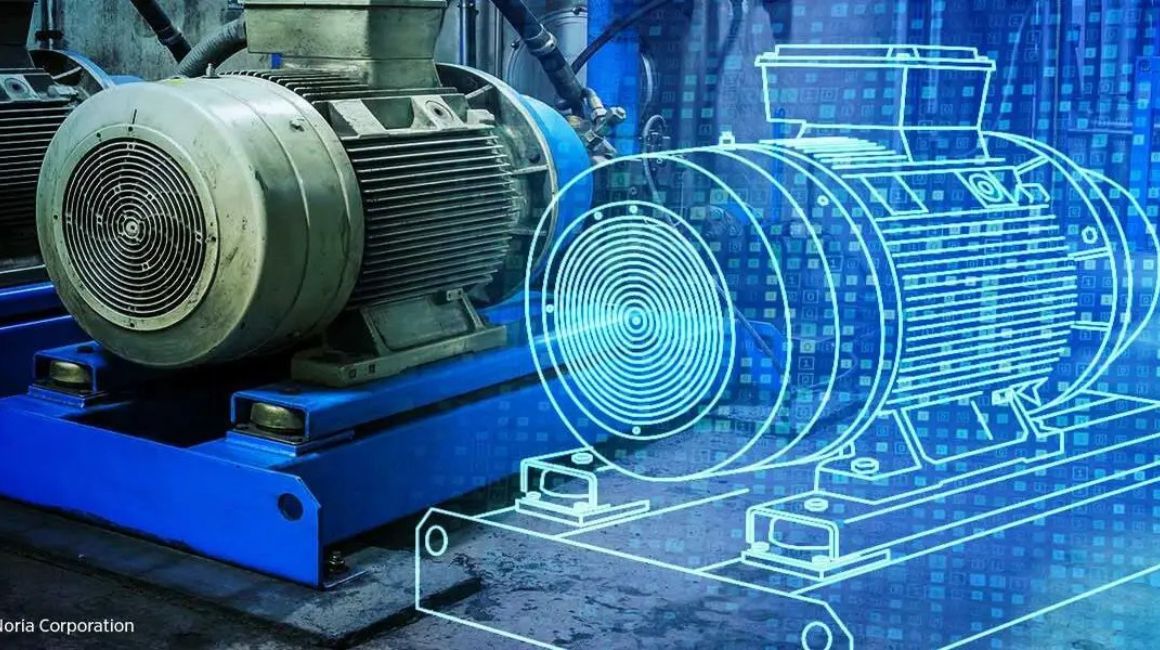

Digital twin technology for real-time simulation

Digital twins integrate real-time sensor data with detailed system models to simulate different operating scenarios, predict system behavior under various conditions, optimize maintenance schedules, test operational changes, and evaluate improvement opportunities. These capabilities enable continuous improvement without production risks or operational disruptions.

Digital twin benefits include optimization testing without production disruption, predictive accuracy improvements of 35-45%, maintenance optimization that reduces costs by 25-30% while improving equipment reliability, and operational efficiency improvements of 20-25% through virtual optimization and testing capabilities.

Machine learning applications across manufacturing sectors

Different manufacturing sectors leverage machine learning technologies in sector-specific ways that address unique industry challenges, operational requirements, and competitive dynamics.

Automotive and heavy machinery

The automotive and heavy machinery sectors are at the forefront of machine learning adoption, using it to enhance production efficiency, quality control, and customer experience. BMW’s Munich plant showcases end-to-end ML integration, improving productivity by 19% and cutting quality issues by 68%. Similarly, heavy machinery makers like John Deere use ML for predictive maintenance and performance optimization, reducing downtime by 45% and boosting efficiency by 28%.

Food and beverage industry

Machine learning in food and beverage manufacturing enhances safety, efficiency, and quality while managing perishable supply chains and meeting regulatory standards. Key applications include contamination detection, shelf life prediction, and automated quality checks. Unilever processes over 4 billion data points daily, cutting costs by 16%, improving delivery by 29%, and boosting quality consistency by 34%

Electronics, semiconductors, and computing

Electronics manufacturing applies machine learning for nanometer-level defect detection, yield optimization, and precision process control. It supports complex assembly, supply chain coordination, and thermal management. TSMC showcases ML success with 99.997% quality rates and 23% profit gains, processing over 2 million inspection points daily with atomic-level accuracy.

Plastic and synthetic material production

Plastic and synthetic material manufacturing applies machine learning to optimize chemical processes, improve material consistency, and reduce environmental impact. Key uses include polymer formulation, extrusion control, and energy-efficient operations. BASF’s global ML systems deliver 21% energy savings, 18% waste reduction, and 14% productivity gains while ensuring quality and compliance.

Furniture and customized manufacturing

Furniture and customized manufacturing use machine learning to streamline production planning, manage custom orders, and enhance personalization. Applications include demand forecasting, quality control for varied materials, and supply chain coordination. IKEA’s ML systems optimize operations across 50 facilities, achieving 17% higher efficiency, 22% better inventory management, and a 26% boost in customer satisfaction.

Real-world success stories: Companies using machine learning in manufacturing

Case studies from global leaders like GE, Siemens, Toyota, and P&G demonstrate the large-scale impact of machine learning in manufacturing. GE’s jet engine plant improved productivity by 22% and cut energy use by 35%, while Siemens’ Amberg factory achieved 99.998% quality and 1,200% productivity gains. Toyota’s ML-enhanced system delivered consistent results across 52 global sites, and P&G reduced operational costs by 19% across 140 facilities while supporting 65 brands worldwide.

Overall, machine learning brings measurable benefits across cost, uptime, quality, and productivity. Companies see 24–34% cost reductions, 29–42% uptime gains, and up to 70% defect rate decreases. Automated quality control, predictive maintenance, and intelligent scheduling are key drivers, enabling continuous improvement and long-term competitive advantage.

The future of machine learning in manufacturing

The evolution of machine learning technologies continues accelerating, with emerging capabilities that will further transform manufacturing operations and create unprecedented competitive advantages for organizations that embrace these developments.

Autonomous production systems

Autonomous manufacturing systems represent the future of machine learning in industry, enabling fully self-managed production with minimal human input. These systems combine AI, robotics, and sensors to optimize operations in real time and adapt to changes autonomously. Tesla’s Gigafactory showcases early success with 99.9% quality and 40% efficiency gains. Early adopters benefit from 24/7 operation, lower labor costs, improved consistency, and enhanced workplace safety.

ML as a driver of sustainability and energy efficiency

Machine learning drives sustainability in manufacturing by optimizing resources, reducing waste, and improving energy and water efficiency. Key applications include energy and water optimization, waste analysis, and eco-friendly supply chain management. On average, ML delivers 20–30% lower emissions, 25–35% less waste, and 22–32% energy savings. Interface Inc.’s Mission Zero shows ML’s full potential, cutting carbon by 96% and water use by 88% while maintaining performance.

As digital transformation accelerates, machine learning in manufacturing is no longer a futuristic concept it’s a critical driver of innovation, efficiency, and competitiveness. From predictive maintenance to intelligent quality control, businesses that embrace these technologies are setting new benchmarks in operational excellence. To stay ahead in this evolving landscape, manufacturers must act now or risk falling behind. For the latest insights, case studies, and trusted technology solutions, follow FBC ASEAN your go-to platform for industrial innovation. Visit our website today to explore how AI and machine learning can power your next phase of growth.